Carbon Steel Hardness Brinell

In materials science hardness is the ability to withstand surface indentation localized plastic deformation and scratching. Steel Hardness conversion calculator.

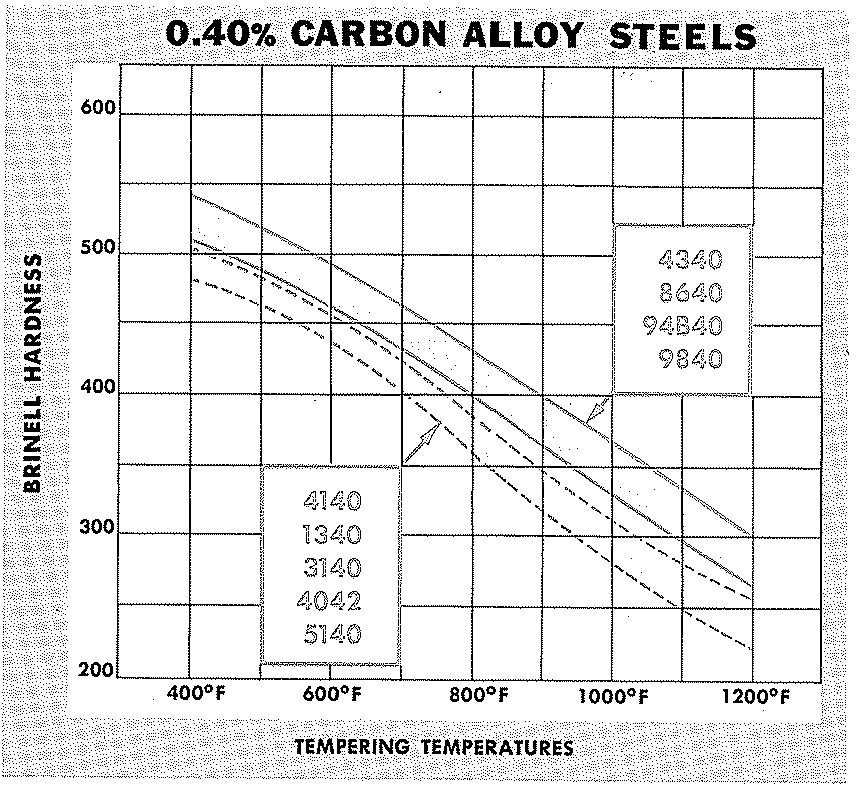

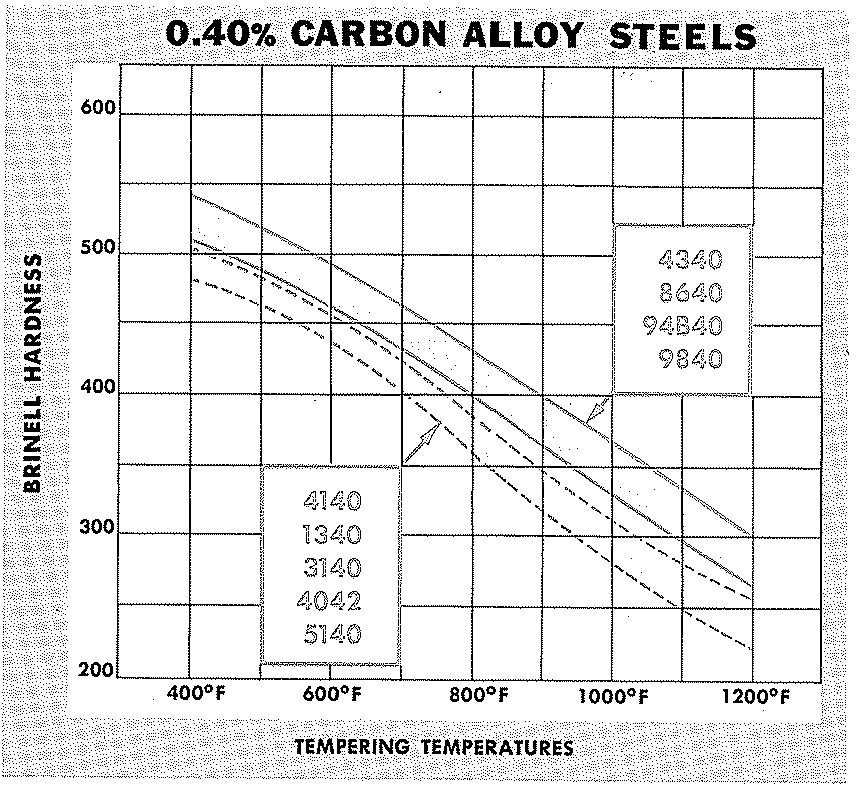

40 Carbon Steel Brinell Hardness Vs Tempering Temperature Precision Machined Products Association

Typical hardnesses of 1095 carbon steel after tempering for 2 hours at different temperatures.

. The Brinell hardness number is designated by the most commonly used test standards ASTM E10-142 and ISO 650612005 as HBW H from hardness B from brinell and W from the material of the indenter tungsten wolfram carbide. Normalized at 885 C 1625 F water quenched from 800-815 C 1475-1550 F. US SAE AISI 1039 1040 1042 1043 1045.

Mangalloy is heat treatable. The basic Brinell hardness of manganese steel is 220 but that with impact wear the surface hardness will increase to higher than 550. 1095 high carbon steel carbon content.

Hardness Vickers converted from Brinell hardness 170. C40 C45 Ck40Ck45 Cm40 Cm45. Hardness Rockwell B converted from Brinell hardness 84.

65Mn steel is a Chinese GB standard spring steel grade Manganese Mn improves hardenability so the strength hardness elasticity and hardenability are higher than that of 65 steel but it has overheat sensitivity and temper brittleness. Enter a figure into any of the fields and click calculate the nearest values in each scale is shown or zero if out of range. As 100 machinability 65.

In former standards HB or HBS were used to refer to measurements made with steel indenters. Values are approximate and for guidance only. Temperature C F Rockwell hardness HRC.

This conversion calculator gives approximate hardness values for various hardness scales based on the Rockwell C Scale. 1020 is a general purpose low tensile low hardenability carbon steel generally supplied in the cold drawn or turned and polished condition with a typical tensile strength range 410 - 790 Mpa and Brinell hardness range 119 - 235. 13 Conversion Table 3 presents data on the relationship among Brinell hardness Vickers hardness Rockwell hardness Rockwell superficial hardness and Knoop hardness of nickel and high-nickel alloys.

KV Steel Services is a supplier of. AR Medium steel plate grades which include AR200 and AR235 have a surface hardness of 180-260 BHN. Steel hardness conversion chart - all values approximate.

Values based on Brinell 10mm Standard Ball 3000kgf. Average dew point 7 C 45 F. Manganese steel is commonly used in the mining industry cement mixers rock crushers crawler treads for tractors rail industry railway switches and.

Machinability based on 100 machinability for AISI 1212 steel 160. American Piping offers this handy conversion calculator for converting the hardness measures of steel pipe using Brinell Rockwell and Tensile values. 1 Hardness Conversion Calculator for metals according to ASTM E140 - 12Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness Vickers Hardness Rockwell Hardness Superficial Hardness Knoop Hardness Scleroscope Hardness and Leeb Hardness.

Figure Comparing Hardness Scales. While not as hard as higher-carbon steels carburizing can increase its surface hardness. Also known as mild steel it is a low-cost material that is easy to shape.

Machinability based on AISI 1212 steel. Hardness Knoop converted from Brinell hardness 184. Vickers - HV.

1020 Bright Carbon Steel Bar. Austenitic steels including carbon alloy and tool steels in the as-forged annealed normalized and quenched and tempered conditions provided that they are homogeneous. Water quenching tends to form cracks.

Hardness Vickers converted from Brinell hardness 126. Brinell Hardness HB Rockwell. The Hardness Tensile Strength relations may vary according to the processing history or the chemical composition of the steel.

Carbon Steel Cast Steel Hardness Conversion. Hardness Knoop converted from Brinell hardness 140. By continuing to browse this website you agree to the use of cookies for statistical purposes as well as third party cookies generated by social network sharing buttons.

It requires more sample preparation and can at times require destruction of a finished part. Hardness Rockwell B converted from Brinell hardness 68. The accuracy of the conversion depends on the.

Brinell Testing is a fairly simple test but the most destructive type. The annealed state has good machinability low cold deformation plasticity and poor. Medium Carbon Steel Composition of 029-054 carbon with 060-165 manganese.

Rockwell B - HRB. Rockwell C - HRC. Conversion for Non-Austenitic Steel Table 1.

Hardness is probably the most poorly defined material property because it may indicate resistance to scratching resistance to abrasion resistance to indentation or even resistance to. Refer to our. What is Manganese Steel Used for.

This hardness level makes AR Medium grades suitable for moderate-wear applications that require more wear resistance than standard mild carbon steel grades but not to the extent of wear resistance needed in applications like mining equipment. Brinell hardness of low-carbon steel is approximately 120 MPa. The Brinell hardness.

205 400 58 HRC. Rockwell Superficial Brinell Vickers Shore Hardness Conversion Chart. A defined load of 500-kg to 3000-kg is applied through a 10 mm hardened steel ball indenter and the subsequent impression is.

Brinell Rockwell Hardness Conversion. Low Carbon Steel Composition of 005-025 carbon and up to 04 manganese. Characterised by excellent weldability very good machinability with reasonable strength and very good ductility.

080M40 is a very popular grade of through-hardening medium carbon steel which is readily machinable in any condition.

Hardness Of Materials Brinell Mohs Material Properties

Average Brinell Hardness Values Hb Download Table

Corrosion Fatigue Analysis Of Medium Carbon Steel C45 Final Year Project Analysis Material Science Corrosion

A Yield Strength Tensile Strength And Brinell Hardness Versus Download High Resolution Scientific Diagram

Comments

Post a Comment